Thermal dissipation verification

During braking, a certain amount of heat develops which must be dissipated by the brake.

It is therefore necessary to check that this amount of heat is compatible with the number of operations per hour that the brake must perform.

Formula 4

(Case A)

\( L=\frac{I_{TOT}\cdot\left ( \frac{2\pi n_{0}}{60} \right )^{2}}{2} \) \( \cdot \) \( \left ( \frac{M_{f}}{M_{f}-M_{L}} \right ) \)

Formula 5

(Case B)

\( L=\frac{I_{TOT}\cdot\left ( \frac{2\pi n_{0}}{60} \right )^{2}}{2} \) \( \cdot \) \( \left ( \frac{M_{f}}{M_{f}-M_{L}} \right ) \)

Formula 6

(Case C/D)

\( L=\frac{I_{TOT}\cdot\left ( \frac{2\pi n_{0}}{60} \right )^{2}}{2} \)

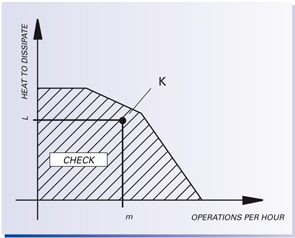

Knowing the number of manoeuvres/hour to be executed, enter the "Chart 1" and check that point K is below the limit curve of the selected brake type.

If this is not the case, switch to a higher "dash" and repeat the operation.

Air-gap adjustment with 0.1mm wear

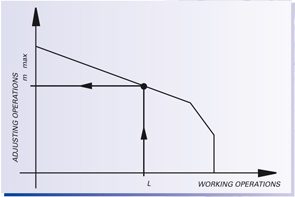

The maximum number of manoeuvres \( m_{max} \) possible before recording the air gap is obtained with "Chart 2".

Entering the abscissae axis with work \( L \) to dissipate and read on the yards of the selected brake curve the number of total manoeuvres. In terms of time (hours), the adjustment is obtained with the following formula:

\( H_{reg}=\frac{m_{max}}{m}\)

The above formula allows the calculation of the consumption equal to 0.1mm air gap. The functionality of the brake is guaranteed for a maximum air gap value of 0.7mm (consumption 0.5mm).