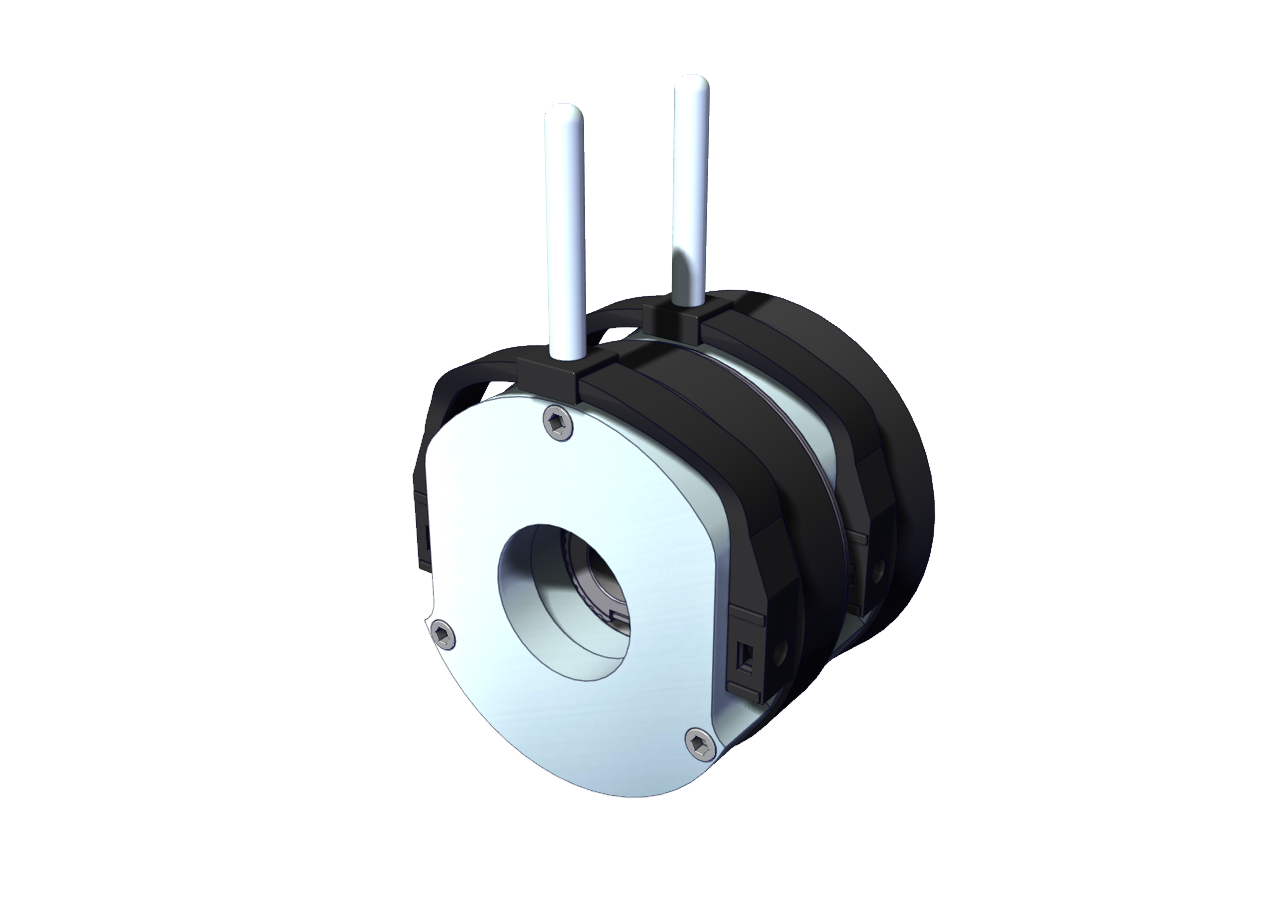

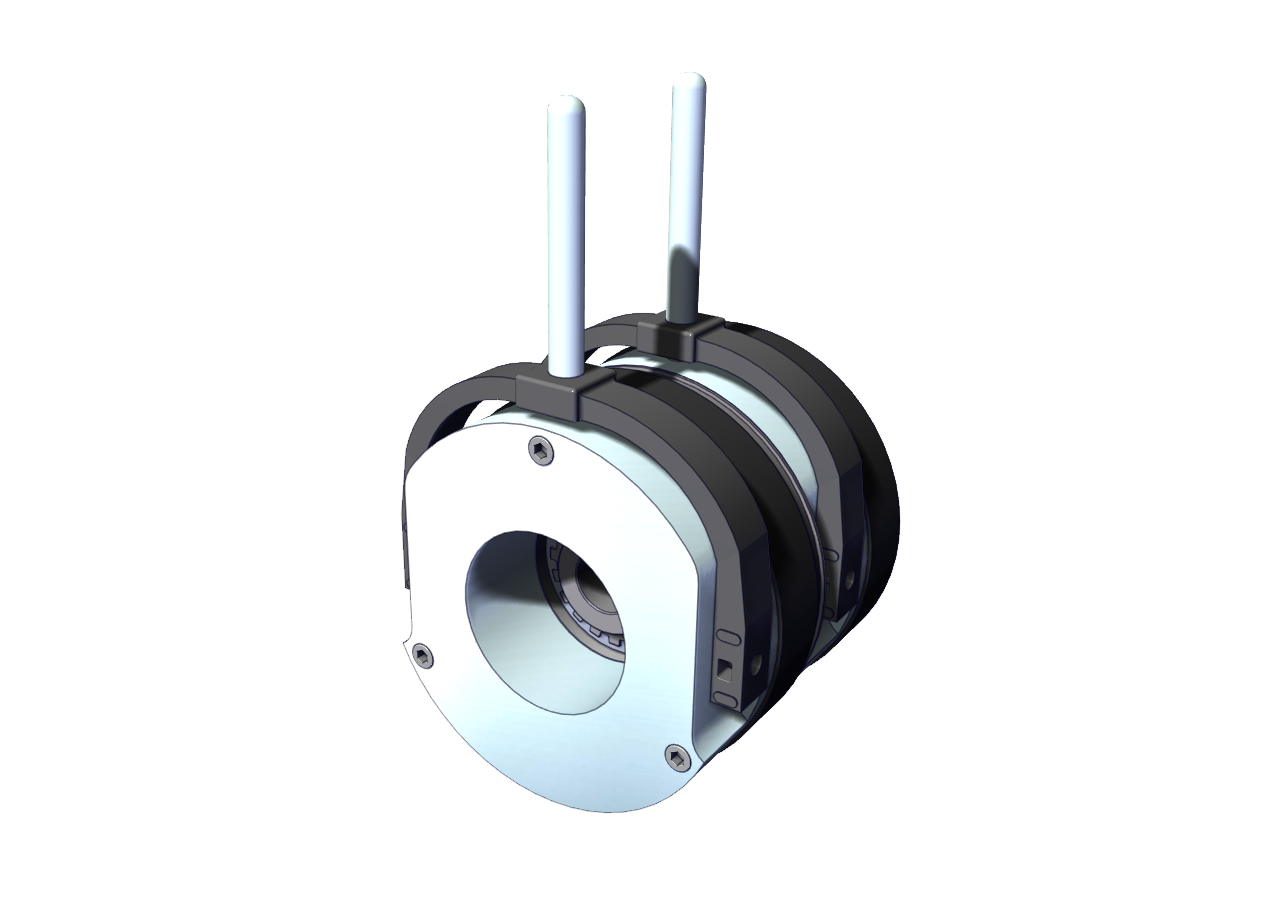

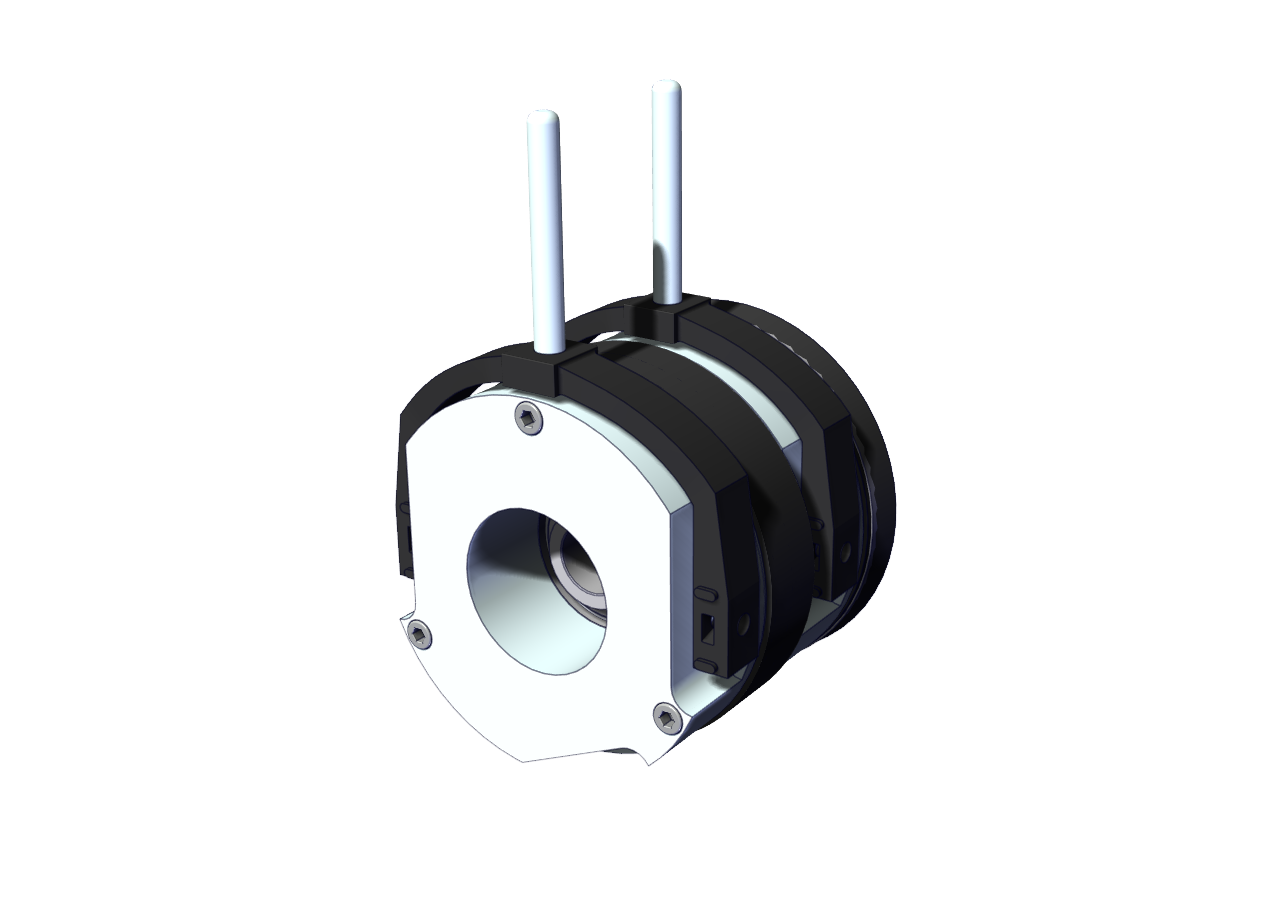

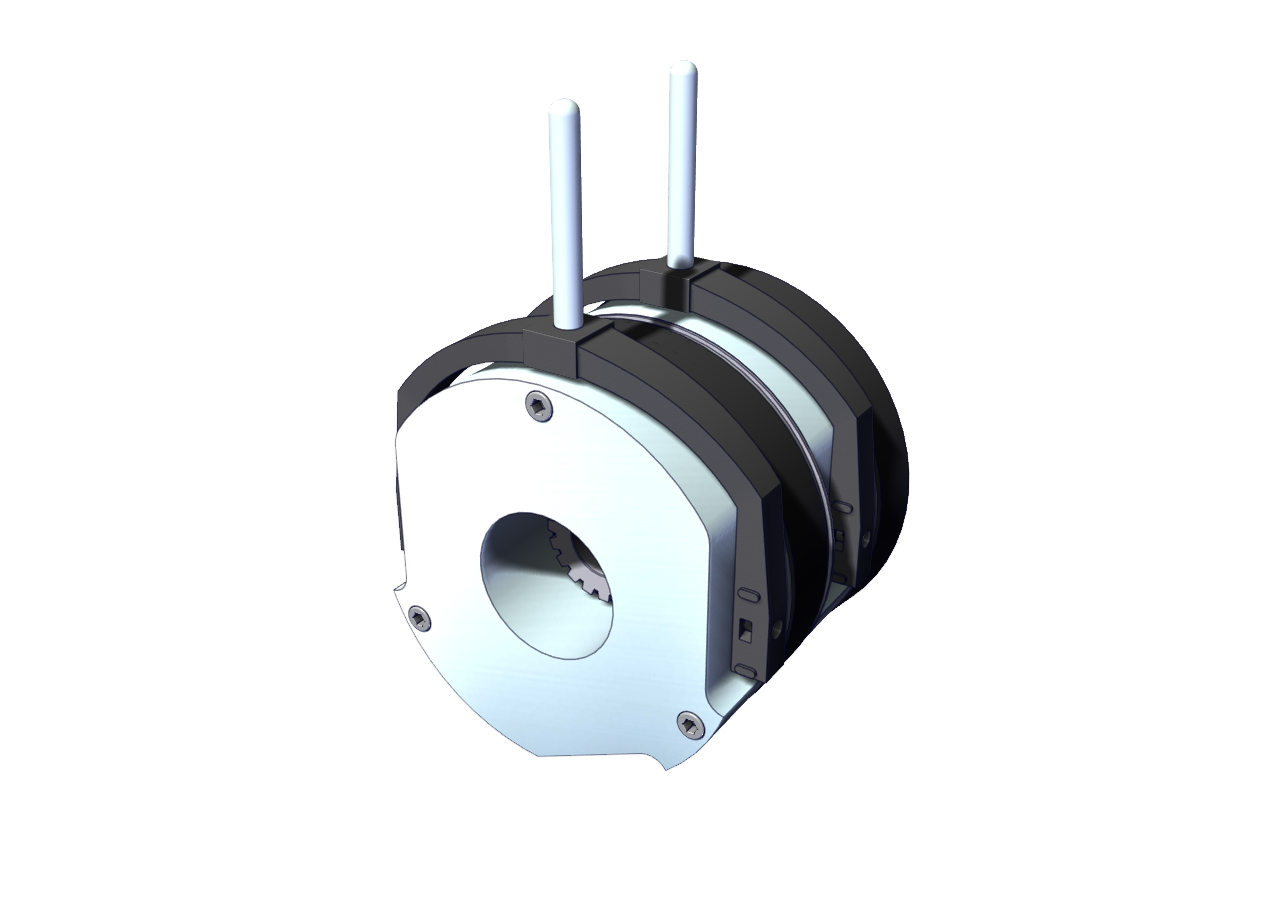

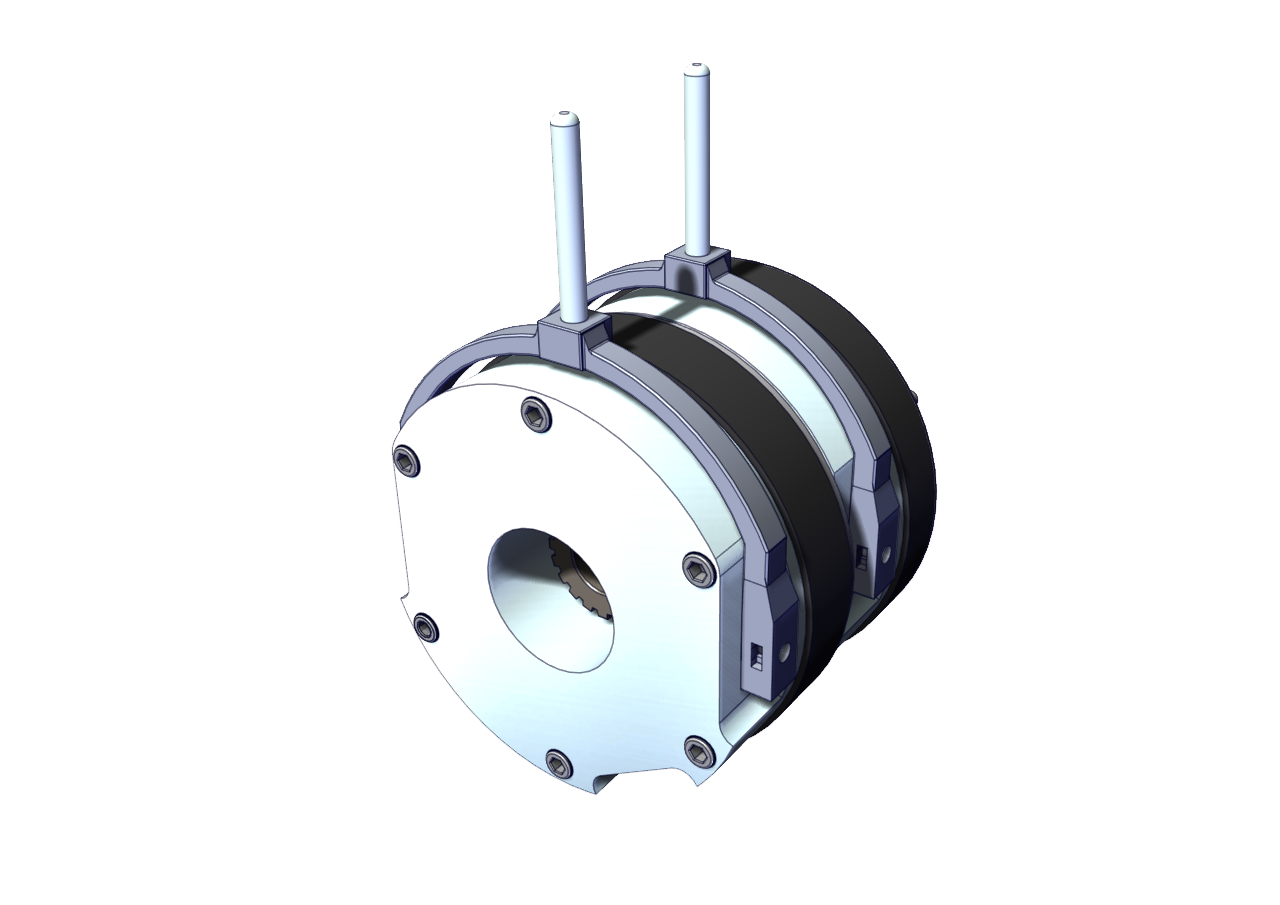

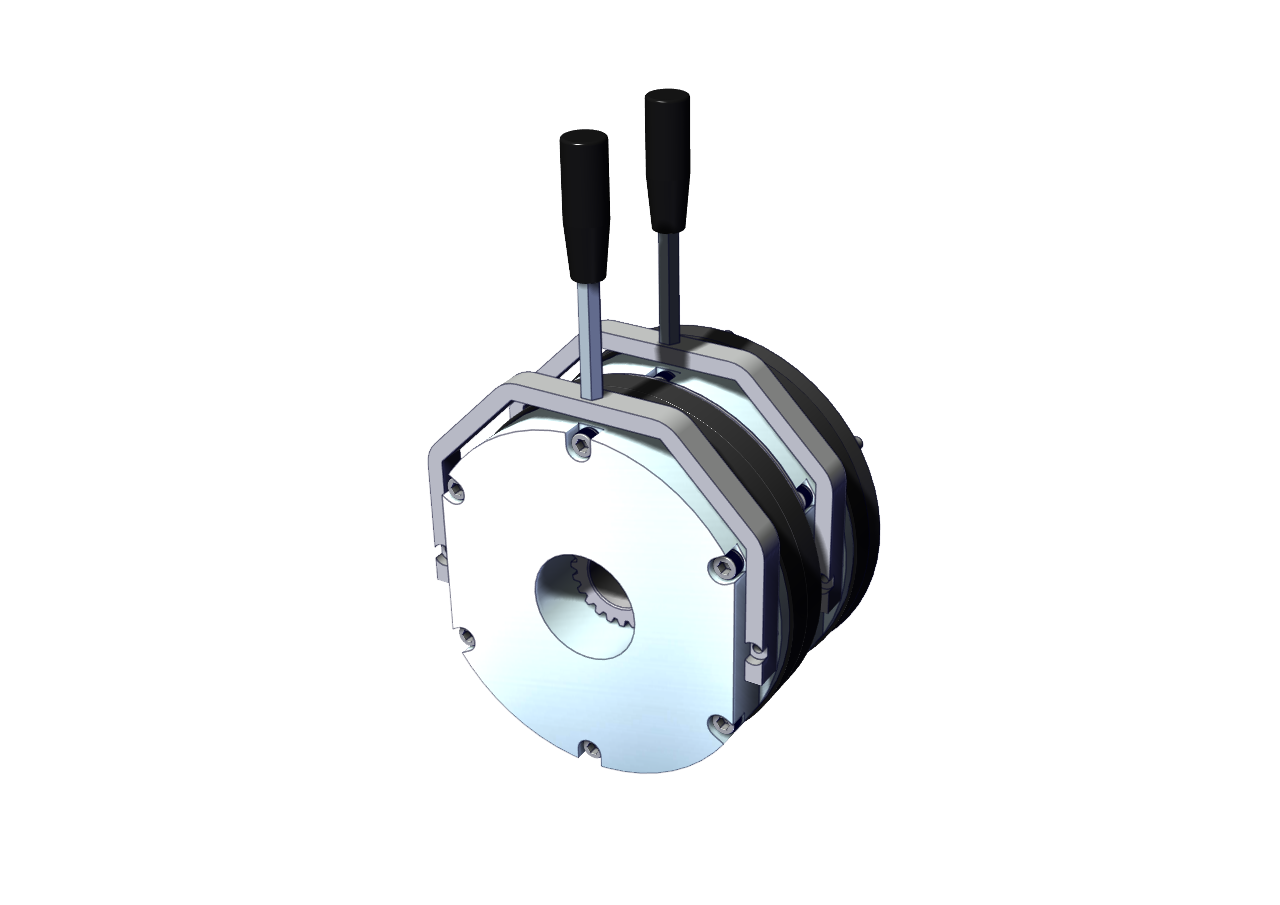

The electro-mechanical spring brake KTH series is an DC brake. The purpose of the brake is to determine the stopping of the rotational movement of a mechanical shaft. To do this, the user must ensure that the brake meets the requirements of the "Brake calculation" section. Only under these conditions can the brake perform its work properly.

The main features of the KTH series brake are:

- Very sturdy structure;

- Silent operation (< 40 dBA in accordance with directive 98/37/EEC);

- Economical thanks to the simple assembly of the brake unit;

- Good heat dissipation. This is done via the fan and/or motor cover, which must necessarily be made of cast iron or steel as it also acts as a braking surface;

- The coil of the electromagnet is completely cemented with epoxy resin, unless otherwise specified, and the mechanical parts are protected by galvanic treatment of galvanizing;

- The manual release lever is included

- cCSAus n° 70043342

The on and off times as well as the functionality in insulation class F and functional class S1, with ventilation are only guaranteed with the use of rectifiers manufactured by Temporiti Srl, for all DC brakes listed on this website, and if the nominal voltage remains within the tolerance limits of the coil's functionality.

Code | Current | Static Braking Torque (Nm) | MAX Motor Speed (RPM) | MAX Power (W) | Weight (kg) |

Continue | 10+10 | 3600* | 20 | 4 | |

Continue | 12+12 | 3600* | 25 | 4.5 | |

Continue | 16+16 | 3600* | 30 | 7.2 | |

Continue | 35+35 | 3600* | 45 | 11.5 | |

Continue | 60+60 | 3600* | 60 | 16.5 | |

Continue | 90+90 | 3600* | 70 | 27.4 | |

Continue | 150+150 | 3600* | 85 | 32.3 | |

Continue | 250+250 | 1800 | 100 | 50.4 | |

(*) For electric motor speeds higher than 2000 (rpm), please contact our technical department in order to check the compliance of the noise generated during braking with the 2006/42/EC standard.